If you want to know “how waste tires are turned into high-value rubber granules” or “what the real profit of a tire rubber granule plant is”, this article will explain the plant’s processes, equipment, applications, and profits in full detail—so you can decide if opening a tire rubber granule plant is worth it.

I. First, Understand: The “Key Role” of Tire Rubber Granule Plants in the Recycling Chain

Many people confuse “rubber granules” with “rubber powder”, but granule plants are actually the “connecting link” in waste tire recycling:

- Upstream Connection: Receive “steel-free tire crumbs” and turn them into “0-5mm high-purity rubber granules”

- Downstream Connection: Granules can be directly sold to sports facility and road construction customers, or used as “raw materials for rubber powder plants”

- Core Value: The produced granules have “99.9% purity and 99% fiber removal rate”, making them “high-demand products that downstream customers compete for”

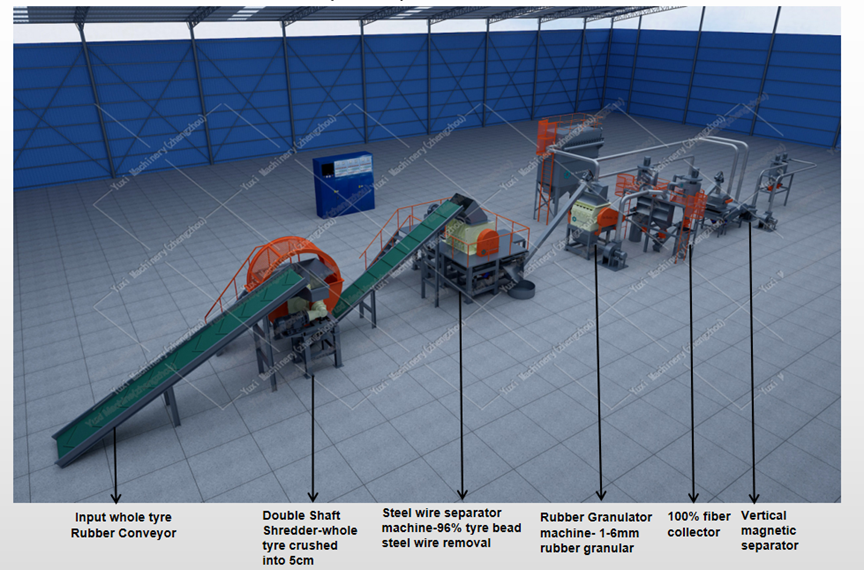

II. 10 Core Processes of a Tire Rubber Granule Plant

A qualified rubber granule plant does not “simply grind tires”; instead, it relies on 10 processes to ensure the “purity and uniformity” of the granules:

- Bead Steel Removal: First Peel Off the “Hard Part”

Use a bead steel remover to completely peel off the steel bead at the edge of the tire, avoiding equipment damage in subsequent processes—the separated steel can be sold for “3000 yuan/ton”, earning 15% more than mixing it in crumbs. - Tire Cutting: Cut the Whole Tire into 4-5 Pieces

Use a tire cutter to cut waste tires into 4-5 pieces, facilitating the shredding process and increasing processing efficiency by 25% compared to “feeding whole tires directly”. - Tire Shredding: Turn into 50mm Rubber Blocks

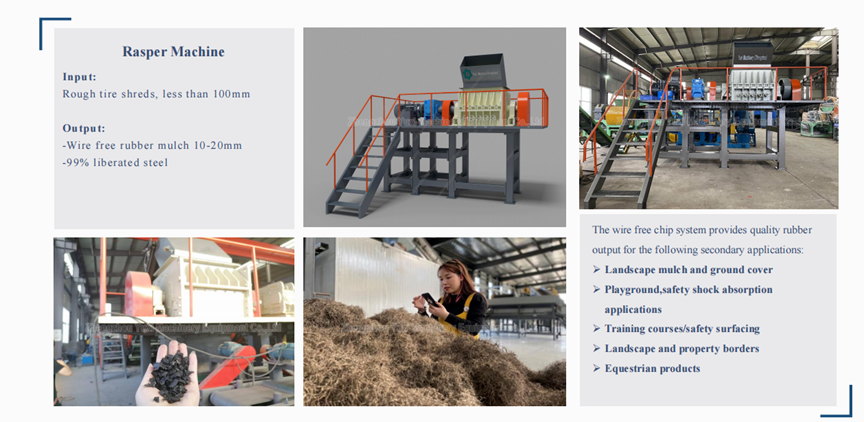

Use a tire shredder to turn cut tire pieces into 50mm rubber blocks; the blades use “water cooling technology” to prevent rubber from sticking due to high temperature, increasing product qualification rate by 5%. - Rough Grinding: Turn into 10-20mm Rubber Crumbs

Use a rough grinder to turn rubber blocks into 10-20mm crumbs; the equipment has a built-in “automatic slag discharge” function to filter out impurities in advance, achieving 100% raw material utilization. - Primary Magnetic Separation: Separate Residual Steel

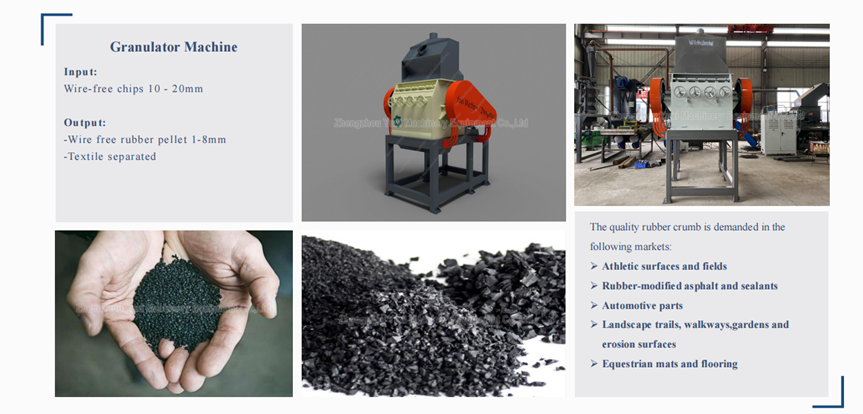

Use a primary magnetic separator to absorb residual steel in crumbs, with a separation rate of 97%; the separated steel can be pressed into “100kg steel cakes” and purchased by steel mills at “high-quality scrap steel” prices. - Fine Grinding: Turn into 1-6mm Rubber Granules

Use a fine grinder to turn crumbs into 1-6mm rubber granules; the equipment uses “impact grinding technology”, making the granule uniformity 12% higher than traditional grinders. - Secondary Magnetic Separation: Ensure No Steel Residue

Use a secondary magnetic separator to separate steel again, with a separation rate of 99%, ensuring “no visible steel wire in the granules” and enabling direct connection with “high-requirement customers”. - Vibratory Classification Screen: Classify by Particle Size

Use a vibratory classification screen to divide rubber granules into 0-1mm, 1-3mm, and 3-5mm specifications, facilitating the needs of different customers and increasing the premium space by 20% compared to “bulk products”. - Return Material Collection: Re-grind Unqualified Materials

Use a return material collector to send oversized granules back to the grinder, avoiding waste and achieving 100% raw material utilization. - Fiber Separation: Remove the Last Trace of Fiber

Use a fiber separator to separate residual fiber from rubber granules, with a fiber removal rate of 99%, bringing the granule purity to 99.9%.

III. 4 High-Value Applications of Tire Rubber Granules

Rubber granules are not “low-cost raw materials”; different specifications correspond to different high-profit scenarios:

- Sports Facilities: 0-1mm granules are used for plastic runways and artificial turf filling, a “must-have” for schools and stadiums, selling for 2000-2500 yuan/ton

- Road Construction: 1-3mm granules are used for rubber asphalt and road shock-absorbing layers, extending road life by 30%, selling for 1800-2200 yuan/ton

- Building Decoration: 3-5mm granules are used for floor tiles and rubber mats, an “environmental choice” for shopping malls and kindergartens, selling for 1900-2300 yuan/ton

- Rubber Products: All specifications of granules can be used as “raw materials for rubber powder plants”, selling for 1700-2000 yuan/ton

IV. Core Equipment Advantages of Tire Rubber Granule Plants

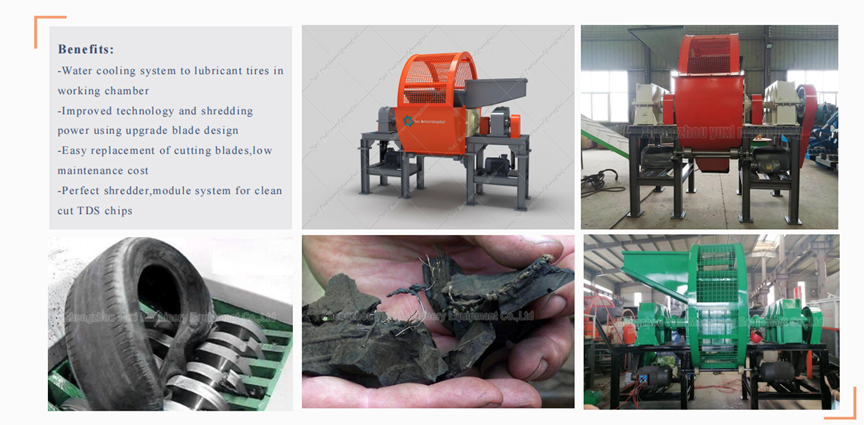

Shredder: Dual-Shaft Opposed Cutting + Water-Cooled Chamber

- Dual-shaft opposed cutting technology makes rubber blocks “uniform in size”, saving effort in subsequent grinding

- Water-cooled chamber prevents rubber from sticking due to high temperature, extending blade life by 30%

- Blades can be replaced individually, reducing maintenance costs by 50% compared to “whole blade replacement”

Grinder: Air + Water Cooling Dual Temperature Control

- Combined air and water cooling keeps rubber granule temperature ≤40℃, ensuring no performance degradation

- Uses “graded grinding technology”, with granule uniformity reaching 98%

- Easy-to-disassemble design, requiring only 20 minutes for cleaning and maintenance

Magnetic Separator: High Gradient + Drum Design

- Magnetic field strength reaches 12000 Gauss, capable of absorbing “micron-level steel debris”

- Drum design prevents rubber granules from “being adsorbed on the equipment”, increasing processing efficiency by 20%

V. Real Profit Calculation for a Tire Rubber Granule Plant

Taking a medium-sized granule plant with a daily processing capacity of 15 tons as an example:

- Raw Material Cost: Steel-free tire crumbs, 700-900 yuan/ton

- Operating Cost:

◦ Electricity: 100 kWh/ton × 1 yuan/kWh = 100 yuan/ton

◦ Labor: 2 people × 200 yuan/day ÷ 15 tons ≈ 27 yuan/ton

◦ Maintenance: 18 yuan/ton

- Revenue:

◦ 0.4 tons of 0-1mm granules (2200 yuan/ton) → 880 yuan

◦ 0.3 tons of 1-3mm granules (2000 yuan/ton) → 600 yuan

◦ 0.2 tons of 3-5mm granules (2100 yuan/ton) → 420 yuan

◦ 0.1 tons of fiber (200 yuan/ton) → 20 yuan

- Profit per Ton: 880+600+420+20 – (700+100+27+18)=1075 yuan

- Annual Profit: 15 tons/day × 300 days × 1075 yuan/ton=4,837,500 yuan

VI. Key Considerations for Opening a Tire Rubber Granule Plant

Choose the Right Raw Materials

- Prioritize “steel-free tire crumbs” to avoid additional steel separation costs

- Do not choose “severely aged tire crumbs”, as they will affect the elasticity and service life of the granules

Connect with Customers in Advance

- Sign “intent orders” with sports facility engineering companies and asphalt mixing plants 3 months before commissioning

- Provide free samples to customers for testing and start mass production only after obtaining “qualification certification”

Meet Environmental Protection Requirements

- Equip with a “baghouse dust collector + activated carbon adsorption” system, with dust concentration ≤10mg/m³

- Use a “sound insulation cover” to wrap the grinder, with noise ≤75 decibels

VII. Frequently Asked Questions

Q1: How much does it cost to open a rubber granule plant?

A: For a medium-sized plant with a daily processing capacity of 15 tons, the total investment (equipment + space + environmental assessment) is about 800,000-1,000,000 yuan.

Q2: What is the shelf life of rubber granules?

A: In a dry and ventilated warehouse, the shelf life is up to 2 years, with no impact on performance.

Q3: Will equipment failures affect production?

A: Equipment suppliers provide “spare parts”, and faulty parts can be replaced within 24 hours without delaying production.

VIII. Conclusion: Tire Rubber Granule Plants Are a “Stable Profit Business”

If you:

- Are a recycler with a stable source of “steel-free tire crumbs”

- Want to produce “high-value finished products” instead of selling “low-priced crumbs”

- Have resources to connect with sports facility and road construction projects

Opening a tire rubber granule plant is a “stable profit choice”—it turns “low-priced crumbs” into “high-profit granules”, allowing you to earn “the most stable part of the profit” in the waste tire recycling industry chain.