Are you searching for “tire rubber powder production details” or “how to achieve 99.7% pure rubber powder”? Tire rubber powder recycling equipment turns waste tires into 20-120mesh high-purity rubber powder—using 11 physical processing steps at room temperature to remove 99.7% of steel and fiber, with zero secondary pollution. Today, we break down its full workflow, equipment specs, and real-world applications.

Ⅰ. What is Tire Rubber Powder Recycling Equipment? Core Function

Tire rubber powder recycling equipment is an integrated “crumb-to-powder” system that combines coarse crushing and fine grinding in one plant. It takes rubber granules from upstream processing and refines them into 20-120mesh fine powder, with 99.7% purity and consistent particle size. The system also recycles steel wire (97-98% pure) and textile fiber (99.9% separated), creating 3 usable products from a single waste stream.

Its key value includes:

- Producing 20-120mesh rubber powder that meets industrial standards for construction, sports surfaces, and energy applications.

- Full resource utilization: steel wire is sold for melting, fiber is used as high-calorific fuel, and rubber powder replaces virgin rubber in manufacturing.

- Room-temperature operation with wind-water cooling, which preserves rubber’s physical properties and avoids thermal degradation.

Ⅱ. 11-Step Processing Flow of Tire Rubber Powder Recycling Equipment

The system’s complete workflow covers every stage from whole tire to fine powder:

- Debeader Machine: Removes the steel bead from the edge of whole tires, ensuring the tire can be cut and shredded without damage to downstream equipment.

- Tyre Cutter Machine: Cuts whole tires into 4-5 large pieces, reducing their size to fit into the shredder and improving processing efficiency.

- Tire Shredder: Shreds cut tire pieces into 50mm rubber blocks, reducing the tire’s volume by 70% and preparing it for finer processing.

- Tire Rasper Machine: Uses rotating rasping rollers to turn 50mm blocks into 10-20mm wire-free rubber chips, loosening and separating 99% of the steel wire from the rubber.

- No.1 Magnetic Separator: Uses a high-strength magnetic drum to separate 97% of the steel wire from 10-20mm rubber chips, collecting the wire for baling and sale.

- Granulator Machine: Processes 10-20mm wire-free chips into 1-8mm rubber granules, with initial fiber separation to remove loose textile material.

- No.2 Magnetic Separator: Removes residual steel wire from 1-8mm granules, increasing the steel sorting rate to 99% and ensuring the rubber is free of metal contaminants.

- Vibrating Grading Screen: Screens 1-8mm granules to select the optimal size (1-4mm) for the grinding mill, returning oversize material for re-crushing.

- Collector: Gathers unqualified or oversized material from the grading screen and sends it back to the granulator for reprocessing, ensuring uniform particle size.

- Fiber Separator: Uses air separation and screening to remove 99.9% of textile fibers (nylon, polyester, rayon, aramid) from the granules, producing clean rubber for grinding.

- Rubber Grinding Mill: Uses rotating grinding rollers to turn 1-4mm granules into 20-120mesh fine powder, with wind-water cooling to maintain powder quality and prevent overheating.

Ⅲ. Core Equipment Parameters of Tire Rubber Powder Recycling

Each machine in the system has precise specifications to ensure consistent output:

- Tire Rasper Machine:

Input: Rough tire shreds <100mm

Output: 10-20mm wire-free rubber mulch, 99% liberated steel

Motor Power: 75-160 HP

Processing Capacity: 1.1-5.5 short tons/hour - Magnetic Separator:

Input: 10-20mm rubber chips (mixed with steel wire and fiber)

Output: 97-98% pure steel wire; rubber + fiber (sent to next stage)

Magnetic Field Strength: 14,500-18,000 Gauss

Drum Diameter: 12-20 inches - Tire Granulator Machine:

Input: 10-20mm wire-free chips

Output: 1-8mm wire-free rubber pellets, fiber-separated

Motor Power: 55-110 HP

Processing Capacity: 0.8-4.4 short tons/hour - Fiber Separator:

Input: Rubber granulate + fiber

Output: 99.9% textile-free rubber granulate; 99.9% textile fiber

Air Flow Rate: 1,200-2,000 CFM - Rubber Grinding Mill:

Input: 1-4mm rubber granulate

Output: 20-120mesh rubber powder, 99.7% pure fine powder

Motor Power: 100-215 HP

Processing Capacity: 0.5-2.2 short tons/hour

Ⅳ. 6 Core Features of Tire Rubber Powder Recycling Equipment

The system is designed to meet industrial recycling needs with these key advantages:

- Integrated System: Combines crumb production and fine grinding in one plant, reducing space requirements and simplifying operation.

- High-Efficiency Grinding: Produces uniform fine powder with high output, with a 99.7% purity rate for 20-120mesh powder.

- Temperature Control: Uses wind and water cooling to maintain powder quality, preventing thermal degradation of rubber properties.

- Low Power Consumption: PLC-controlled design with energy-saving components, reducing electricity costs by 15-20% compared to traditional grinding systems.

- Easy Operation: Manufactured with PLC control, requiring only 1-2 operators and simple troubleshooting.

- Durable & Reliable: Long-term stable operation with minimal downtime, thanks to high-wear-resistant components and modular design.

Ⅴ. 6 Industrial Applications of Tire Rubber Powder

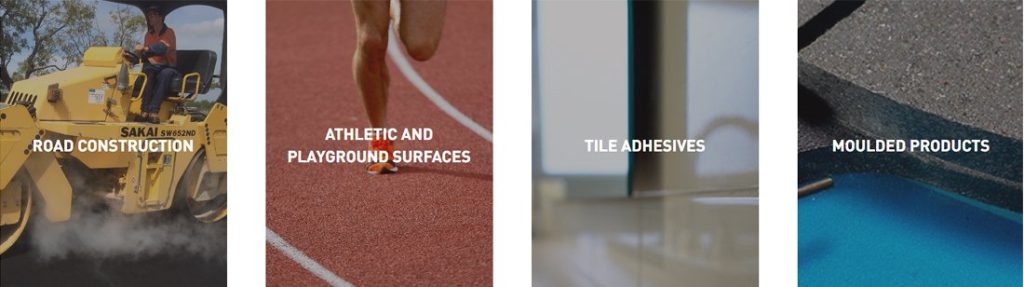

Refined 20-120mesh rubber powder serves 6 key sectors:

Road Construction:

- Rubberized asphalt for roads and driveways, improving crack resistance and skid resistance.

- Shock-absorbing materials for bridge bearings and highway noise barriers.

Sports Facilities:

- Running tracks, artificial turf infill, and tennis court surfaces, providing cushioning and durability.

Industrial Products:

- Seals, shoe soles, rubber mats, and shock absorbers, replacing 20-30% of virgin rubber.

Environmental Products:

- Recycled soles, recycled rubber boards, and filters, reducing plastic waste in manufacturing.

Energy:

- Tire-derived fuel (TDF) for cement kilns and industrial boilers, replacing coal and reducing carbon emissions.

Rubber & Plastic Products:

- Pipe insulation, garbage cans, and wire/cable insulation, improving product flexibility and cost-effectiveness.

Tire rubber powder recycling equipment is a “one-stop solution” for turning waste tires into high-value 20-120mesh rubber powder—through 11-step physical processing, it achieves 99.7% purity, full resource utilization, and zero secondary pollution. It supports sustainable construction, manufacturing, and energy sectors, making it a critical asset for circular economy projects aiming for zero waste and stable returns.