Ever wondered how waste tires are turned into high-value rubber powder and contribute to environmental protection? This article comprehensively elaborates on the processing technology, multi-field application scenarios, environmental advantages, industry challenges, and common Q&A of tire rubber powder recycling, helping you fully grasp the core value of this circular economy project.

I. What is Tire Rubber Powder Recycling? Understand Its Core Logic in 3 Minutes

Globally, more than 12 million tons of waste tires are processed into rubber powder each year. This recycling mode refers to the process of separating, grinding, modifying and purifying waste tires through professional equipment to obtain 80-200 mesh fine rubber powder. Compared with rubber granules, it has finer particle size, stronger compatibility with other materials, and more diversified application scenarios, which is an important part of the deep recycling of waste tires.

According to data from the Rubber Manufacturers Association (RMA), the recycling rate of tire rubber powder in North America has increased from 38% in 2019 to 54% in 2024. Every ton of rubber powder recycled can reduce 1.2 tons of carbon dioxide emissions, save 3.5 barrels of crude oil equivalent raw materials, and reduce the occupation of land resources by 0.8 cubic meters, which has significant environmental and economic benefits.

II. Processing Flow of Tire Rubber Powder Recycling: 5 Core Steps to Create High-Quality Powder

The production of tire rubber powder has higher requirements on fineness and uniformity than rubber granules, and the whole process needs to go through 5 strict links:

- Tire Disassembly and Classification

First, waste tires are sent to a tire disassembling machine to separate the tread, sidewall and bead ring. The bead ring (metal part) is recycled separately, and the tread and sidewall rubber are classified—tread rubber has higher rubber content and better wear resistance, which is used to produce high-grade rubber powder; sidewall rubber is used to produce ordinary rubber powder after processing. At the same time, the internal fiber layer of the tire is initially removed to reduce subsequent impurity removal pressure. - Low-Temperature Cryogenic Brittle Treatment

The classified rubber blocks are cut into 5cm-long rubber strips, which are then sent to cryogenic freezing equipment. Under the environment of -70℃ to -80℃, the rubber strips are frozen for 15-20 minutes to make the rubber material brittle. This step can avoid the problem of rubber melting and molecular structure damage caused by high temperature during grinding, and ensure the performance of rubber powder. - Multi-Stage Gradient Grinding

The brittle rubber strips enter the coarse grinder first, and are ground into 40-mesh coarse powder; then they are sent to the fine grinder, and the grinding disc gap is adjusted according to the required fineness to produce 80-120 mesh medium powder; if 150-200 mesh fine powder is needed, it is further ground by a superfine grinder. Each grinding link is equipped with a temperature control device to keep the grinding temperature below 20℃. - Precision Impurity Removal and Modification

The ground rubber powder is first screened by an airflow sieve to separate unqualified coarse particles, and then enters the electrostatic impurity removal equipment to remove residual metal (content ≤0.1%) and fiber impurities. For rubber powder used in high-end fields (such as asphalt modification, rubber product regeneration), surface modification is required—adding silane coupling agent, stearic acid and other modifiers to improve the compatibility and bonding force between rubber powder and asphalt, plastic and other materials. - Drying, Packaging and Storage

The modified rubber powder is sent to a low-temperature dryer (drying temperature 45℃) to reduce the moisture content to below 2%, then sealed and packaged with a vacuum packaging machine (25kg/bag or 500kg/big bag). The finished product is stored in a warehouse with humidity ≤40% and temperature 15-25℃ to avoid oxidation, moisture absorption and caking.

III. Application Scenarios of Tire Rubber Powder Recycling: 4 Emerging Fields Beyond Traditional Uses

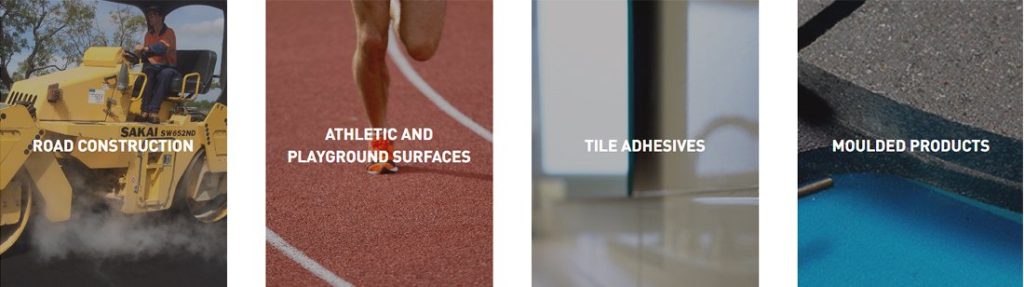

Tire rubber powder, with its excellent elasticity, wear resistance and compatibility, has broken through the traditional application scope and been widely used in 4 major fields:

Modified Asphalt for Transportation Infrastructure

Adding 10-15% rubber powder to asphalt can improve the crack resistance of pavement by 45%, high-temperature stability by 35% and low-temperature flexibility by 30%. At present, more than 60% of highway reconstruction projects in the United States use rubber powder modified asphalt. For example, the Arizona State Highway, which was paved with rubber powder modified asphalt in 2015, has a service life of 15 years, which is twice that of ordinary asphalt pavement, and the driving noise is reduced by 12-15 decibels.

Regeneration of Rubber and Plastic Products

In the production of rubber conveyor belts, automobile seals, waterproof coils and other products, adding 20-30% rubber powder can reduce raw material costs by 25-30% while maintaining more than 90% of the original product performance. In Europe, 60% of automobile manufacturers use rubber powder regenerated seals, and 45% of waterproof coil enterprises use rubber powder as a key additive.

Building Energy Conservation and Environmental Protection Materials

- Sound insulation materials: Rubber powder mixed with cement, gypsum and other materials to make sound insulation boards, which can absorb 80% of low-frequency noise, and are widely used in walls, floors and ceilings of cinemas, recording studios and high-rise residential buildings.

- Thermal insulation materials: Rubber powder-based thermal insulation mortar has good thermal insulation performance, and its thermal conductivity is 30% lower than that of ordinary mortar. It is used in external wall thermal insulation projects in cold regions of Northern Europe.

- Shock absorption materials: Rubber powder mixed with polyurethane to make shock absorption pads, which are used in the installation of air conditioners, generators and other equipment, reducing vibration transmission by 70%.

New Energy and Emerging Industries

- Lithium battery diaphragm: The modified rubber powder can be used as a filler for lithium battery diaphragms, improving the heat resistance and mechanical strength of the diaphragm by 25% and 18% respectively. At present, 3 major lithium battery manufacturers in the United States have carried out cooperative research and development.

- 3D printing materials: Mixing rubber powder with PLA (polylactic acid) to make elastic 3D printing filaments, which are used in the production of customized products such as orthopedic braces, shoe insoles and robot flexible joints, with 35% lighter weight than traditional materials.

IV. Environmental and Economic Value of Tire Rubber Powder Recycling: 3 Core Advantages

- Solving “Black Pollution” and Protecting the Environment

Every ton of rubber powder recycled can reduce 1.1 tons of waste tires from being landfilled or incinerated. In 2024, the global recycling of tire rubber powder will handle about 12 million tons of waste tires, equivalent to reducing 2300 million cubic meters of landfill space and avoiding 13.2 million tons of carbon dioxide emissions. At the same time, it eliminates the environmental pollution caused by the incineration of waste tires (such as dioxin, sulfur dioxide and other harmful gases). - Saving Non-Renewable Resources

Producing 1 ton of rubber powder can replace 0.8 tons of natural rubber and 0.6 tons of synthetic rubber. Calculated based on the global annual recycling of 12 million tons of rubber powder, it can save 9.6 million tons of rubber raw materials every year, equivalent to the annual output of 240 million rubber trees. In addition, it can save a lot of crude oil resources (1 ton of synthetic rubber needs about 3 tons of crude oil), which eases the pressure on resource supply. - Driving the Development of Circular Economy Industry

The tire rubber powder recycling industry has formed a complete industrial chain of “waste tire recycling → processing → deep application”. In the European Union, the industry has created more than 150,000 jobs, including waste tire recycling, equipment operation, product research and development, and sales. At the same time, it drives the development of related industries such as modified asphalt, rubber products, and building materials, with a total annual output value of more than 20 billion euros.

V. Industry Challenges and Development Trends of Tire Rubber Powder Recycling

Current Main Challenges

- High processing costs: The cost of cryogenic freezing and multi-stage grinding accounts for 40% of the total production cost, which is 30-40% higher than that of rubber granules. Small and medium-sized enterprises are facing greater cost pressure.

- Uneven product quality: Due to the lack of unified industry standards in some regions, the fineness, impurity content and modification effect of rubber powder produced by different enterprises vary greatly, which affects the market recognition.

- Limited application promotion: In some developing regions, the acceptance of rubber powder modified products is low, and the application scenarios are not fully developed.

Future Development Trends

- Technological innovation to reduce costs: The development of “normal temperature efficient grinding technology” and “energy-saving cryogenic equipment” is expected to reduce the production cost by 20-25% in the next 3-5 years.

- Standardization of the industry: The European Union has issued the “Tire Rubber Powder Quality Standard” (EN 15940), which specifies 18 indicators such as fineness, impurity content and tensile strength. It is expected to become a global universal standard.

- Expansion of high-end application fields: With the development of new energy, 3D printing and other industries, the demand for high-performance rubber powder will increase by 15-20% annually, and the application proportion in high-end fields will exceed 50% by 2030.

VI. Common Questions About Tire Rubber Powder Recycling: 5 Key Answers

- What is the price range of tire rubber powder?

The price varies according to fineness and quality: 80-mesh ordinary rubber powder is 280-380 euros/ton; 120-mesh medium-grade rubber powder is 380-480 euros/ton; 200-mesh modified rubber powder is 500-650 euros/ton. The price of rubber powder for special fields (such as lithium battery diaphragm) can reach more than 1000 euros/ton. - What is the maximum proportion of rubber powder that can replace new rubber?

In rubber products: 20-30% for high-performance products (such as automobile seals), 40-50% for general products (such as rubber hoses); in asphalt modification: the optimal proportion is 10-15%; in building materials: 15-25% can be added according to performance requirements. - What is the shelf life of tire rubber powder?

Under the condition of sealed and dry storage, the shelf life is 2 years. After unpacking, it should be used up within 6 months to avoid oxidation and hardening caused by contact with air. - Can individuals recycle waste tires and sell them to recycling factories?

Yes. Most recycling factories recycle waste tires at 1.2-1.8 euros/kg. If the tires are disassembled into rubber strips and the metal parts are removed, the recycling price can be increased by 10-15%. It should be noted that the recycled tires should be free of serious oil pollution and damage. - Does tire rubber powder have pungent odor?

Formal recycling factories will carry out “deodorization treatment” in the production process—using activated carbon adsorption and ozone oxidation to remove volatile organic compounds (VOCs). The finished rubber powder has only a slight rubber smell, which will dissipate completely within 24 hours, and the VOCs emission meets the EU EN 717-1 standard.