A comprehensive guide to the core processes, 6 major energy application scenarios, and 7 technical advantages of the physical processing system of Tire Wire Free Mulch Plant.

In the tire recycling industry chain, the Tire Wire Free Mulch Plant is a key link for “removing steel wire and producing pure materials” — it can process used tires into 99.9% steel-wire-free rubber chips, solving the impurity problem in tire recycling and providing high-purity raw materials for “tires-to-energy” conversion. Today, we will detail: How does this equipment achieve no secondary pollution? What are its application scenarios and technical advantages?

I. The “Steel Wire Separation Black Technology” of Tire Wire Free Mulch Plant: From Mixed Materials to Pure Materials

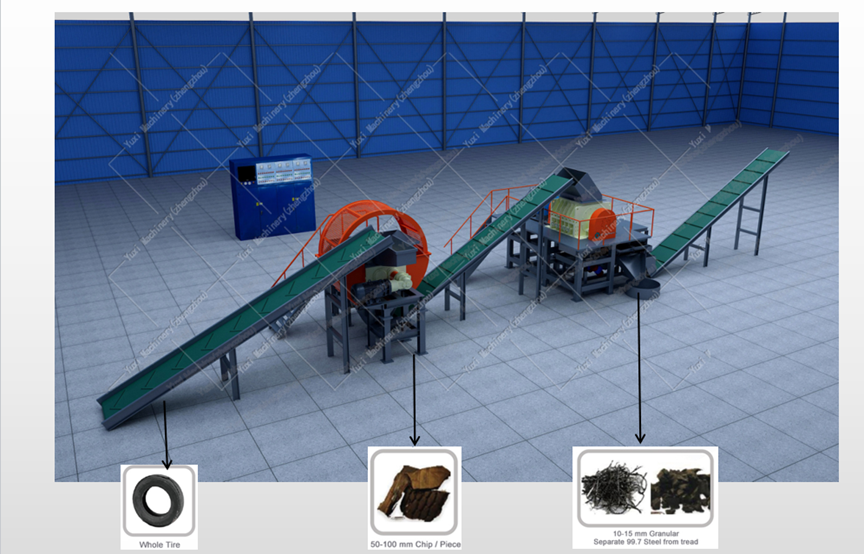

As the second step in the tire recycling system, this equipment completes the transformation from “used tires with steel wire” to “steel-wire-free rubber chips” through pure physical processing, with the entire process centered around four core logics: “loosening, peeling, capturing, and matching”.

- Adaptive Raw Material Adaptation

Used tires are directly fed into the system via a conveyor belt without manual classification — the built-in size recognition module of the equipment automatically adapts to different specifications of tires (such as car tires, truck tires, and engineering tires), with a feeding efficiency of up to 200 tires per hour, avoiding the impact of raw material differences on subsequent separation effects. - Graded Shredding to Loosen Steel Wire

The equipment first performs initial rough shredding on the complete tire, breaking it into 10-15cm large rubber pieces; then conducts secondary fine shredding to process it into 5-8cm rubber blocks. During this process, the adhesive layer between the rubber and steel wire inside the tire is gradually “loosened”, laying the foundation for subsequent complete separation. - High-Speed Rubbing to Peel Steel Wire

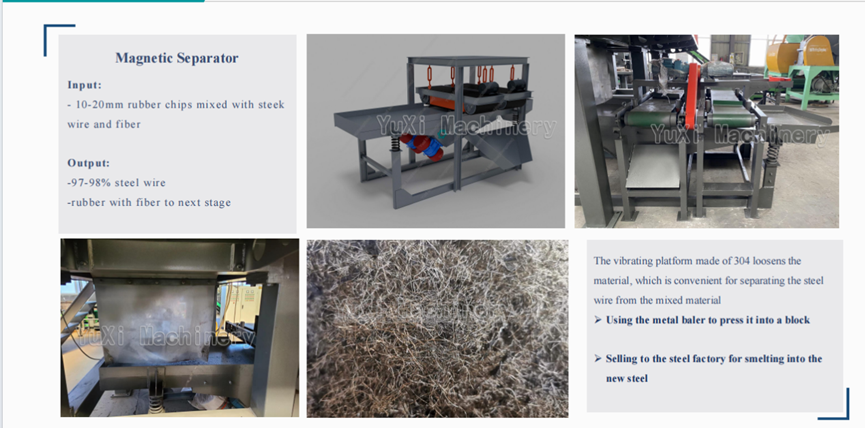

The toothed roller of the rasper rotates at a high speed of 600 rpm, rubbing and squeezing the rubber blocks to completely peel the steel wire embedded in the rubber. At this point, the rubber becomes 10-20mm chips, forming a mixed material with steel wire, waiting for the next sorting step. - Two-Stage Magnetic Separation to Capture Steel Wire

The mixed material first passes through primary magnetic separation with a 1.2T magnetic field strength to adsorb large steel wires, achieving a separation rate of 97%; then enters fine magnetic separation with a 1.5T magnetic field strength to capture residual fine steel wires, increasing the separation rate to 99.9%. The finally separated steel wire will be compressed into blocks and directly sold to steel mills for recycling. - Finished Product Classification to Match Demand

The separated rubber chips are classified through a grading screen into two types of finished products: “10-15mm mulch material” and “15-20mm energy material”, corresponding to different application scenarios respectively, achieving precise matching of raw materials and demand.

II. 6 Major Energy Application Scenarios of Steel-Wire-Free Rubber Chips: From Cement Plants to Power Plants for “Tires-to-Fuel”

The steel-wire-free rubber chips processed by the equipment are most valuable as high-calorific-value fuel, widely used in multiple energy scenarios:

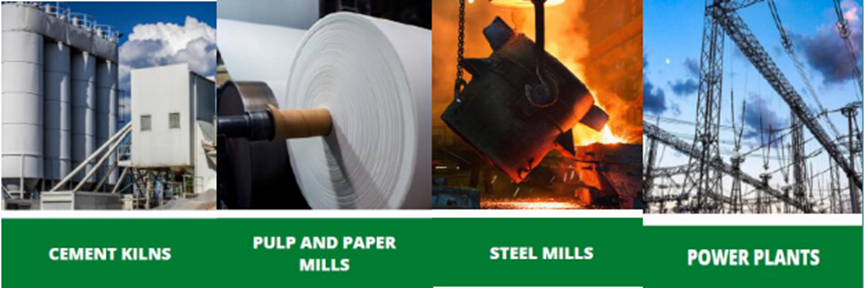

- Fuel for Cement Kilns

Rubber chips have a calorific value of about 4000 kcal/kg and can replace 30% of coal for cement kiln calcination, reducing the fuel cost of cement plants and lowering carbon emissions. - Fuel for Pulp and Paper Mills

In the cooking process of pulp and paper mills, rubber chips can be used as auxiliary fuel to improve thermal energy utilization efficiency — 1 ton of rubber chips can replace about 0.8 tons of coal. - Industrial and Utility Boilers Fuel

Used for heating in factory and public facility boilers, rubber chips have good combustion stability and low ash content, without causing additional wear to the boiler. - Civil Engineering Applications

In subgrade filling, pipeline insulation and other projects, rubber chips can be used as lightweight filling materials, while having thermal insulation and shock absorption effects — about 0.5 tons of rubber chips are needed per cubic meter of subgrade. - Other Tires-to-Energy Facilities

In professional tire-to-energy conversion plants, rubber chips can be processed into TDF (Tire-Derived Fuel) for power generation or heating — 1 ton of rubber chips can generate about 3000 kWh of electricity. - Clean Cut TDF Chips for Further Processing

Steel-wire-free rubber chips can be further processed into clean TDF chips for high-end energy scenarios, with a market price 20% higher than ordinary rubber chips.

III. 7 Technical Advantages of Tire Wire Free Mulch Plant: Why Is “Pure Physical Processing” More Popular?

This equipment can become a “core tool” for tire recycling, supported by 7 major technical advantages:

- Efficient Steel Wire Removal

Multi-stage magnetic separation technology can remove 99.9% of steel wire, ensuring the purity of rubber chips is sufficient for high-end applications and avoiding product quality issues caused by impurities. - Pure Physical Processing System

Full physical processing is adopted, operating at room temperature without chemical reactions and no secondary pollution, meeting environmental protection requirements. - Adjustable Rubber Chip Size

It can produce 10-20mm rubber chips, and the size can be adjusted according to customer needs to adapt to the usage requirements of different scenarios. - Multi-Product Output

It can produce high-purity rubber chips and separate sellable steel wire, realizing “one raw material, two incomes”. - Automated Operation

Equipped with a PLC control system, it is easy to operate and stable in production, without the need for a large number of manual on-duty, reducing labor costs. - Environmental Protection and Energy Saving

It operates at room temperature with low energy consumption and no emissions, meeting industrial requirements under the “dual carbon” goal. - Wide Adaptability

It can process various used tires such as car tires, truck tires, and engineering tires, with a wide range of applications and no restrictions on raw material types.

The Tire Wire Free Mulch Plant achieves 99.9% steel wire separation through “pure physical processing + two-stage magnetic separation” black technology, and more importantly, achieves no secondary pollution, turning used tires from “impure waste” into “high-value energy raw materials”. Its 6 major energy application scenarios make “tires-to-fuel” a reality; its 7 major technical advantages make the recycling process more environmentally friendly and efficient. Under the trend of circular economy, this equipment not only solves the problem of used tire disposal but also opens up a new track for “tires-to-energy” — every such equipment is reducing the burden on the earth and creating new value for the industry.