A comprehensive guide to the 3-stage core processes, 6 major energy application scenarios, and 5 automated technical advantages of Tire TDF Plant, revealing the industrial code of “tires-to-fuel”.

When cement plants and power plants start using “tires as fuel”, many people wonder: How are used tires turned into clean alternative fuel? More importantly—how much coal can tire TDF fuel replace? The answer lies in the Tire TDF Plant — through mechanical shredding and steel wire separation, it converts used tires into high-calorific-value, low-pollution TDF (Tire-Derived Fuel), solving the tire recycling problem and providing a sustainable alternative to traditional energy. Today, we will detail: How does a tire TDF plant operate? What are the replacement ratio and application value of TDF fuel?

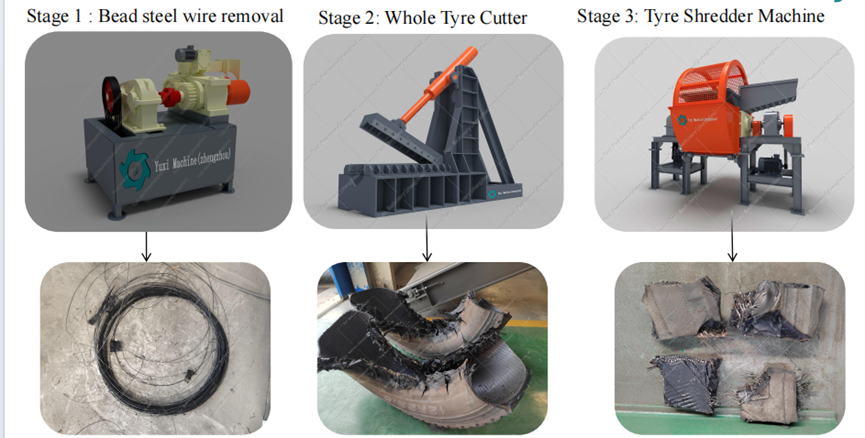

I. The 3-Stage Core Process of Tire TDF Plant: From “Used Tires” to “Clean TDF Fuel”

The core of tire TDF plant is “pure physical processing + no chemical pollution”, completing the transformation from “tires to fuel” through 3 stages, with no high temperature or emissions throughout:

- Stage 1: Bead Steel Wire Removal

First, professional equipment is used to remove the bead steel wire from the edge of the tire. This is the first step of “impurity removal” — the equipment can adapt to tires of 650-1200mm size, processing 40-45 pieces per hour. The removed bead steel wire can be directly recycled for steelmaking, laying the foundation for subsequent shredding. - Stage 2: Whole Tire Cutting

The tire with bead steel wire removed is sent to the Whole Tire Cutter. The blade driven by the hydraulic system cuts the tire into 3-4 sections, with a cutting efficiency of up to 40-45 pieces per hour. The cut tire sections are uniform in size, facilitating the next shredding step. - Stage 3: Tire Shredding

The cut tire sections enter the Tire Shredder Machine, which uses 450mm diameter double-shaft blades to shred at high speed, producing 50-100mm rubber blocks. The shredder uses 40Cr blades (hardness 55-58 HRC), processing 3000kg of tires per hour. Finally, uniform rubber chips with minimal steel wire residue are obtained, which are clean TDF fuel.

II. 6 Major Core Application Scenarios of Tire TDF Fuel: “Energy Alternative Solutions” from Cement Plants to Power Plants

TDF fuel processed through 3 stages has a calorific value of up to 4000 kcal/kg, widely used in 6 energy scenarios, becoming an ideal alternative to traditional fossil fuels:

- Fuel for Cement Kilns

TDF can replace 30% of coal for cement kiln calcination. Each ton of TDF can reduce carbon emissions by about 0.8 tons and lower the fuel cost of cement plants by 15%. - Fuel for Pulp and Paper Mills

In the cooking process of pulp and paper mills, TDF can be used as auxiliary fuel to improve thermal energy utilization efficiency by 20%. Each ton of TDF can replace about 0.8 tons of coal. - Fuel for Industrial and Utility Boilers

TDF has good combustion stability and low ash content. Used for heating in factory and public facility boilers, it does not cause additional wear to the boiler. Each ton of TDF can generate heat equivalent to about 3000 kWh of electricity. - Civil Engineering Applications

TDF can be used as lightweight material for subgrade filling, with thermal insulation and shock absorption effects. About 0.5 tons of TDF are needed per cubic meter of subgrade, while reducing construction waste. - Other Tires-to-Energy Facilities

In professional energy conversion plants, TDF can be directly used for power generation or heating. 1 ton of TDF can meet the electricity demand of an ordinary family for 3 months. - Clean-Cut TDF Chips for Further Processing

TDF can be further processed into 50-100mm clean chips for high-end energy scenarios, with a market price 20% higher than ordinary TDF.

III. Environmental Advantages of Tire TDF Fuel: Why Is “Tires-to-Fuel” a Green Choice?

TDF fuel has become a “new favorite” in the energy industry not only because of its high calorific value, but also because of its environmental characteristics:

- No Secondary Pollution

TDF production uses pure physical processing throughout, with no chemical additives or high-temperature combustion, and does not produce harmful gases such as dioxins, meeting EU environmental standards. - Reduced Carbon Emissions

Each ton of TDF used can reduce carbon dioxide emissions by about 0.8 tons, equivalent to the carbon sequestration of 40 trees in one year. - Full Utilization of Used Tires

TDF plants can process various used tires such as car tires, truck tires, and engineering tires, realizing “100% tire resource utilization” and avoiding pollution caused by tire landfilling or incineration. - Reduced Waste Disposal Pressure

About 1.5 billion used tires are produced globally every year. TDF plants can convert these “black wastes” into energy, reducing the pressure on landfills.

IV. 5 Technical Advantages of Tire TDF Plant: Why Is “Automated Processing” More Popular?

Tire TDF plant can become the core carrier of “tires-to-fuel”, supported by 5 major technical advantages:

- Fully Automated Operation

Equipped with a PLC control panel and conveyor belt automatic feeding system, it can monitor and adjust production parameters in real time, supporting automatic processing of car tires and truck tires without a large number of manual on-duty. - Safety-First Design

Built-in emergency stop buttons, overload protection, and blade locking mechanisms to avoid safety hazards during production and ensure stable operation of the equipment. - Dual-Specification Fuel Output

It can produce 50-100mm TDF fuel according to demand, adapting to the combustion requirements of different scenarios and meeting the differentiated needs of cement plants and power plants. - Low Downtime and Maintenance Costs

Blades adopt a replaceable design with a service life of up to 2000 hours. Cutting blades are easy to replace, and maintenance costs are 30% lower than traditional equipment. - High Processing Efficiency

It can process 2-20 tons of mixed car/truck tires per hour, with high shredding efficiency and low energy consumption. One equipment can process about 50 tons of used tires per day.

Tire TDF plant converts used tires into high-calorific-value clean fuel through “3-stage pure physical processing + environmental advantages”, solving the environmental problem of tire recycling and providing a sustainable solution for the energy industry. Its 6 major application scenarios turn “tires-to-fuel” from a concept into reality; its 5 major technical advantages make the production process more efficient and safe. Driven by the “dual carbon” goal, tire TDF plant is not only the “destination of used tires”, but also a “new track for circular economy” — every such plant is reducing the burden on the earth and creating new energy value for the industry.