A comprehensive guide to the 10 core processes, 4 major application scenarios, technical advantages, and industrial value of tire rubber crumb recycling, with a focus on deciphering the secrets of steel wire and fiber separation.

When you step on a plastic running track or walk on rubber asphalt pavement, the elastic texture under your feet is likely the result of tire rubber crumb recycling — globally, more than 1 billion used tires are produced each year, and through processing by professional “Tire Rubber Crumb Plants”, they can be converted into rubber crumbs with a purity of 99.9%. The key to this transformation lies in how to accurately separate the steel wire and fiber from the tires. Today, we will answer in detail: How are steel wire and fiber completely separated in tire rubber crumb recycling? What are the core equipment and separation techniques?

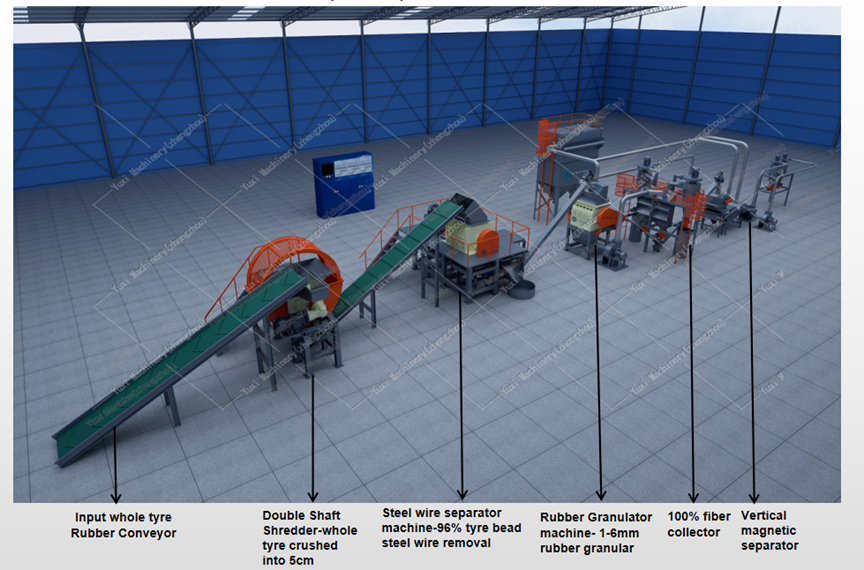

I. The 10 Core Processes of Tire Rubber Crumb Recycling: From “Steel-Belted Tires” to “High-Purity Crumbs”

Tire rubber crumb recycling is not simply “shredding”, but a refined separation and processing system where the separation of steel wire and fiber runs through the entire process. Professional rubber crumb plants achieve the goal of “impurity removal and uniform particle size” through 10 processes:

- Step 1: Debeader Machine

First, remove the bead steel from the tires. This is the first step in separating steel wire, which can avoid damage to subsequent equipment by hard metal objects, while recovering large pieces of steel wire in advance to reduce the pressure of subsequent separation. - Step 2: Tyre Cutter Machine

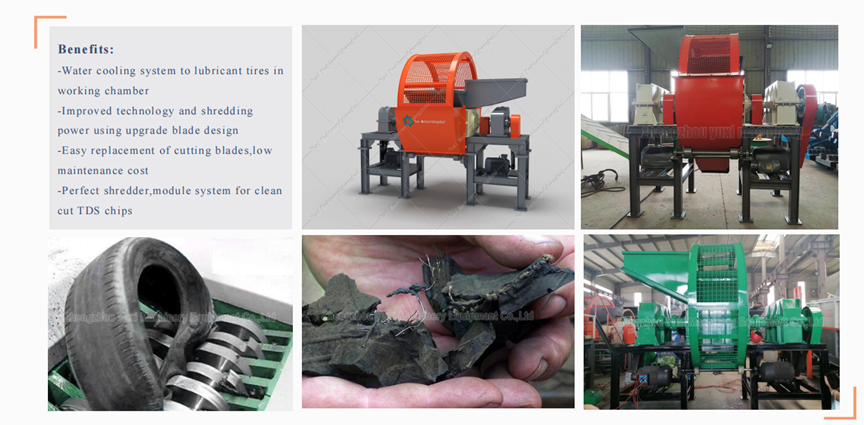

Cut the complete used tire into 4-5 pieces, each weighing 20-30 kg, to facilitate smooth entry into the next crushing process. The uniform cutting not only makes manual handling easier but also ensures more even crushing in the subsequent steps, laying the foundation for the initial separation of steel wire and fiber. - Step 3: Tire Shredder

Shred the cut tire pieces into 50mm rubber blocks. During the shredding process, the rubber on the tire surface will be initially peeled off from the internal steel wire and fiber, preparing for rubbing and separation. The shredding efficiency can reach 200 tires per hour. - Step 4: Rasper Machine

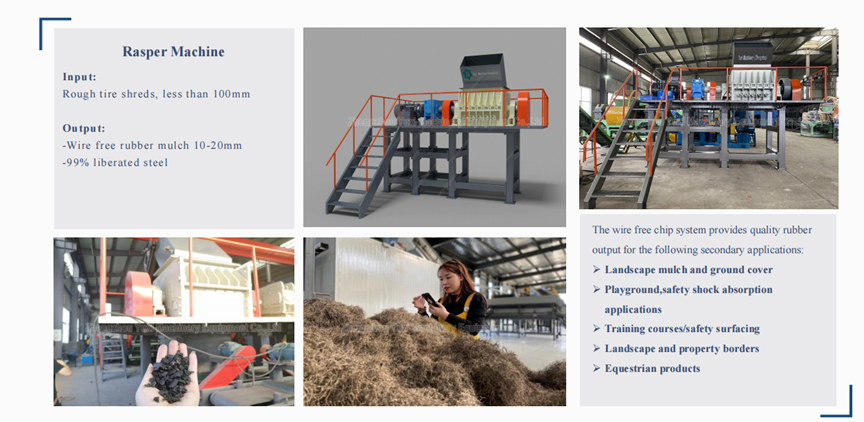

Process the 50mm rubber blocks into 10-20mm rubber chips — this is the core link for the initial separation of steel wire and fiber. The toothed rollers of the rasper rotate at high speed to rub and forcibly peel the rubber from the embedded steel wire and fiber, resulting in a mixture of the three components in the rubber chips. - Step 5: No.1 Magnetic Separator

Separate steel wire for the first time. Utilizing the magnetic properties of steel wire, high-intensity magnetic rollers adsorb steel wire from the mixed rubber chips with a separation rate of 97%, recovering about 50 kg of steel wire per hour, which can be directly recycled for steelmaking. At this stage, a small amount of fine steel wire and fiber still remain in the rubber chips. - Step 6: Granulator Machine

Process the rubber chips into 1-6mm rubber crumbs. During granulation, the remaining fine steel wire and fiber will be further separated from the rubber, while the uniformity and purity of the crumbs are improved, creating conditions for secondary separation. - Step 7: No.2 Magnetic Separator

Separate steel wire for the second time. Adopting a stronger magnetic field than the No.1 Magnetic Separator, it accurately adsorbs the residual fine steel wire after granulation, increasing the separation rate to 99% and ensuring almost no metal impurities in the rubber crumbs. This step is crucial for the complete separation of steel wire. - Step 8: Vibrating Grading Screen

Screen out crumbs of appropriate size and send them to the subsequent process, while returning non-conforming ones to the collector for re-shredding. During screening, some lightweight fibers will float up with the air flow, realizing preliminary fiber separation. The screen replacement cycle is about 1 month, with extremely low maintenance costs. - Step 9: Collector

Recycle materials requiring secondary processing to ensure “no crumb waste”, while collecting the floating fibers during screening and concentrating them into the fiber separator. The overall material utilization rate can reach 99%. - Step 10: Fiber Separator

This is the core equipment for the complete separation of fiber, adopting dual technology of “airflow separation + screen filtration”. Taking advantage of the light weight and easy floating characteristics of fiber, high-pressure airflow blows the fiber out of the rubber crumbs, which are then filtered and collected through a special screen, ultimately achieving complete separation of fiber from rubber crumbs. The separated fiber can be used as high-calorific-value fuel (calorific value of about 4000 kcal/kg), realizing “full utilization of by-products”.

II. 4 Major Core Application Scenarios of Tire Rubber Crumbs: The “Recycled Value” from Tracks to Pipes

After 10 refined processes and complete separation of steel wire and fiber, the high-purity rubber crumbs (0-5mm) have long outgrown the label of “recycled materials” and become “essential materials” in multiple fields:

Construction and Infrastructure Field

- Rubber Asphalt Pavement: Asphalt mixed with rubber crumbs has 40% better aging and cracking resistance, and can reduce driving noise by 3-5 decibels;

- Subgrade Shock-Absorbing Layer: Used in the shock-absorbing structures of bridges and tunnels to improve impact resistance and extend the service life of projects.

Venue and Leisure Facilities

- Plastic Running Tracks: The core raw material of the plastic running tracks we are familiar with is rubber crumbs. Each square meter of running track requires about 20 kg of crumbs, which have both elasticity and wear resistance;

- Children’s Playground Equipment: The buffer layer of slides and climbing frames is filled with rubber crumbs, which can effectively reduce the impact force when falling.

Geotechnical and Environmental Protection Field

- Drainage Pipes: Porous irrigation pipes made of rubber crumbs can achieve the effect of “slow water seepage and soil moisture retention”;

- Soil Conditioner: Mixed into sandy soil to improve water retention capacity, requiring about 100 kg of rubber crumbs per mu of land.

Rubber and Plastic Products

- Pipe Insulation Layer: Used for the insulation of water pipes and heating pipes, with 20% better thermal insulation effect than traditional insulation materials;

- Shoe Soles and Seals: Processed into non-slip shoe soles and equipment gaskets, reducing production costs while improving product durability;

- Cable Insulation Layer: Cable sheaths made of rubber crumbs have better insulation and aging resistance than ordinary plastics.

III. Technical Advantages of Tire Rubber Crumb Recycling: Why Are “High-Purity Crumbs” More Popular?

The ability to produce rubber crumbs with a purity of 99.9% lies in the efficient separation of steel wire and fiber, and the 5 core advantages of this system are thus highlighted:

- High Purity and No Impurities

Through the combined technology of “two magnetic separations + one fiber separation”, the final rubber crumbs have a purity of 99.9%, almost free of steel wire, fiber and other impurities, and can be directly used in high-end product production. - Uniform and Adjustable Particle Size

The particle size can be adjusted between 0-5mm to meet the needs of different scenarios (e.g., 2-4mm crumbs for running tracks, 1-2mm crumbs for asphalt). The uniform particle size benefits from the precise control of the crushing and separation processes. - High Automation

The entire system adopts a circular processing mode, and the separation of steel wire and fiber is fully automated. It can automatically screen and recycle materials, ensuring consistent quality of each batch of crumbs without the need for a large number of manual interventions. - Full Utilization of By-Products

The separated 1% steel wire can be recycled for steelmaking, and 10% fiber can be used as high-calorific-value fuel, realizing “no waste of used tires” and improving the overall recycling efficiency. - Wide Application Range

High-purity rubber crumbs with complete impurity removal can be adapted to the needs of construction, sports, industry and other fields, avoiding product quality problems caused by impurities.

IV. Industrial Value of Tire Rubber Crumb Recycling: More Than “Environmental Protection”, It’s a “New Economic Track”

The value of tire rubber crumb recycling is largely supported by the effective separation of steel wire and fiber — it is precisely because impurities are completely removed that the application scenarios of rubber crumbs are expanded, and the industrial value is correspondingly improved:

- Environmental Aspect: Recycling 1 ton of used tires can reduce about 1 ton of solid waste and save about 0.8 tons of natural rubber resources. The separated steel wire and fiber also realize resource utilization, avoiding secondary pollution;

- Economic Aspect: The market price of 1 ton of high-purity rubber crumbs is about 2500 yuan, the separated steel wire can be sold at 3000 yuan per ton, and fiber at 500 yuan per ton. A crumb plant with an annual output of 1000 tons can achieve an annual profit of more than 2 million yuan;

- Social Aspect: It provides low-cost recycled materials for construction, sports and other industries, promotes the implementation of “circular economy” in more fields, creates jobs, and drives the development of related industries.

The core secret of tire rubber crumb recycling lies in the precise separation of steel wire and fiber — through the combined technology of “two magnetic separations + one fiber separation” and 10 refined processes, it converts “black waste” into rubber crumbs with a purity of 99.9%; through 4 major application scenarios, it brings recycled materials into our lives; through highly automated design, it achieves a win-win situation of “environmental protection and economy”. Driven by the “dual carbon” goals, tire rubber crumb recycling is no longer a “niche industry”, but a “golden track” related to resource sustainability and industrial greening — every efficient separation of steel wire and fiber empowers the “rebirth” of used tires, reduces the burden on the earth, and increases income for the industry.