Are you searching for “tire rubber granule production parameters” or “fiber separation in rubber recycling”? Tire rubber granule recycling equipment is a key stage in waste tire recycling—it processes wire-free chips into 0-5mm high-purity rubber granules, achieving 99.9% impurity removal and uniform particle size. Today, we detail its 10-step flow, equipment specs, and industrial applications.

Ⅰ. What is Tire Rubber Granule Recycling Equipment? Core Role

Tire rubber granule recycling equipment is the “refinement link” in tire recycling—it takes wire-free chips from the Rubber Mulch Plant, removes fibers, and processes them into 0-5mm uniform granules. It also recycles steel (for melting) and textile fibers (for high-calorific fuel), maximizing resource utilization.

Ⅱ. 10-Step Processing Flow of Tire Rubber Granule Recycling Equipment

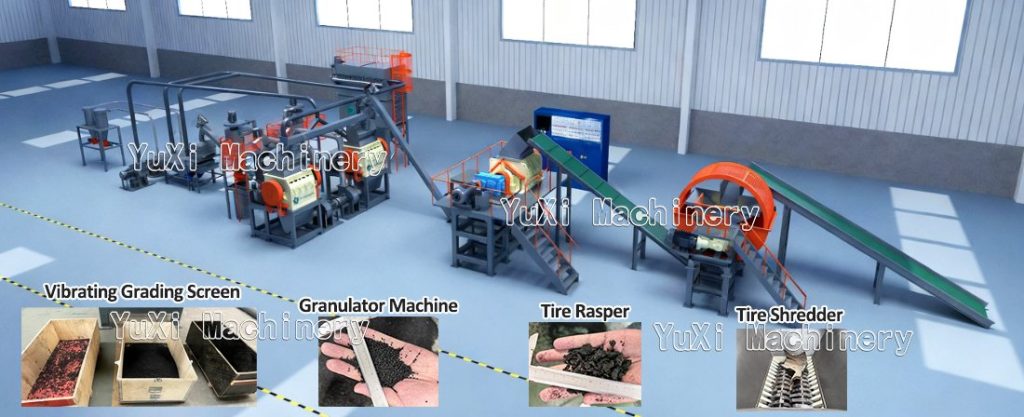

The system’s Process Flow covers full-cycle refinement:

- Debeader Machine: Removes bead steel from whole tires.

- Tyre Cutter Machine: Cuts whole tires into 4-5 pieces.

- Tire Shredder: Outputs 50mm rubber blocks.

- Tire Rasper Machine: Outputs 10-20mm rubber chips.

- No.1 Magnetic Separator: Separates steel wire with 97% sorting rate.

- Rubber Granulator Machine: Outputs 1-6mm rubber granules.

- No.2 Magnetic Separator: Separates residual steel with 99% sorting rate.

- Vibrating Grading Screen: Screens appropriate sizes into the grinding mill.

- Collector: Returns unqualified material for re-crushing.

- Fiber Separator: Separates fiber material from rubber granules.

Ⅲ. Core Equipment Parameters of Tire Rubber Granule Recycling

Key specs for critical machines:

- Tire Rasper Machine: Input <100mm rough shreds; Output 10-20mm wire-free rubber mulch, 99% liberated steel.

- Magnetic Separator: Input 10-20mm rubber chips (with steel/fiber); Output 97-98% pure steel wire + rubber (to next stage).

- Tire Granulator Machine: Input 10-20mm wire-free chips; Output 1-8mm wire-free pellets, fiber-separated.

- Fiber Separator: Input rubber granules + fiber; Output 99.9% textile-free rubber crumb.

Ⅳ. 5 Core Features of Tire Rubber Granule Recycling Equipment

The system’s design meets industrial recycling needs:

- 99.9% Pure Granules: Almost free from impurities like steel and fiber.

- Adjustable 0-5mm Size: Uniform particle size for diverse applications.

- High Automation: Recirculation ensures consistent quality.

- Byproduct Utilization: Steel and fiber are fully recycled for efficient reuse.

- Wide Applications: Fits sports fields, road construction, and eco-friendly building materials.

Ⅴ. Industrial Applications of Tire Rubber Granules

Refined rubber granules serve 3 key sectors:

- Construction: Rubberized asphalt for roads/driveways; bumpers, floor tiles, and foundation waterproofing.

- Geotechnical/Asphalt: Drainage pipes, soil conditioners, porous irrigation pipes, and road repair materials.

- Rubber/Plastic Products: Pipe insulation, garbage cans, shoe soles, and wire/cable insulation.

Tire rubber granule recycling equipment turns “waste rubber chips” into high-value 0-5mm granules—through 10-step refinement, it achieves 99.9% purity and full byproduct reuse. It supports sustainable construction and manufacturing, making it a core asset for circular economy projects aiming for zero waste and high returns.