Are you looking for information on “wire-free tire processing equipment parameters” or “tire shred magnetic separation and purification processes”? As the second step in the tire recycling system, wire-free tire shred recycling equipment can process TDS rubber shreds into 0.4-0.8 inch wire-free rubber pellets with a 99.9% wire removal rate. It uses purely physical processing without secondary pollution and can simultaneously produce recyclable steel wire. Today, we break down its 5-step process, equipment details, and 7 application scenarios.

Ⅰ. What is Wire-Free Tire Shred Recycling Equipment? Core Positioning

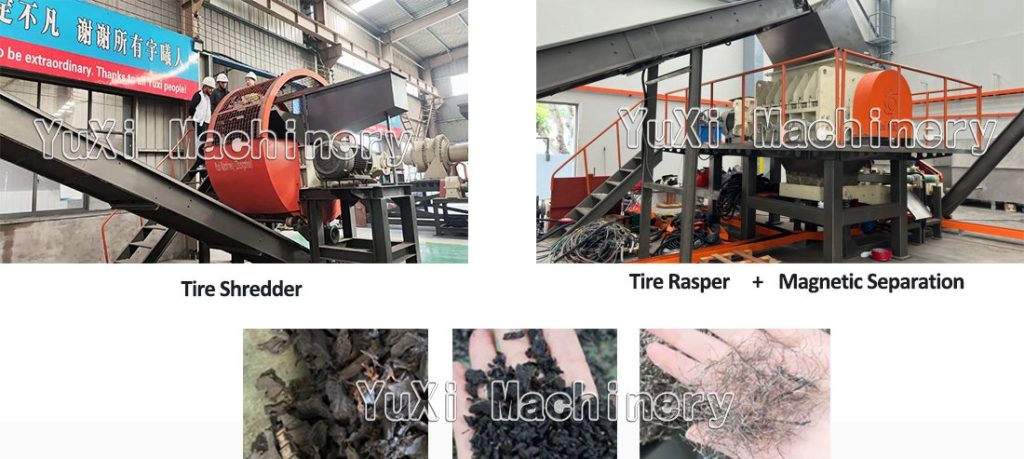

Wire-free tire shred recycling equipment is the “purification link” in the tire recycling system—it takes in coarse shreds (typically <4-inch rubber blocks) from upstream shredding equipment, and through 3 core devices (“shredding → rasping → magnetic separation”), converts steel-containing rubber shreds into 99.9% pure wire-free pellets, while separating steel wire that can be directly sold to smelters.

Its core values are:

- Provide downstream users with “0.4-0.8 inch wire-free rubber pellets” to meet the purity requirements of landscape mulch, sports field surfaces, and other scenarios, avoiding the impact of steel wire on subsequent processing or use.

- Achieve efficient steel wire recycling: a single production line can simultaneously produce 97-98% pure steel wire, which can be further processed with cleaning equipment or directly baled and sold, increasing the overall profit of the recycling project.

Ⅱ. 5-Step Processing Flow of Wire-Free Tire Shred Recycling Equipment

The system’s Process Flow is strictly divided into 5 links, fully automated by conveyors and PLC systems without extensive manual intervention:

- Step 1: Raw Material Input

Waste tires are fed into the system via belt conveyors. Coarse shreds (<4 inches) processed by upstream shredding equipment serve as feedstock and can enter the next step directly without additional sorting. - Step 2: Tire Shredding

A dual-shaft shredder performs initial crushing, cutting whole tires or large rubber blocks into 1.2-2 inch large pellets. The blades are made of high-wear-resistant alloy material (e.g., AISI D2) with a hardness of 58-62 HRC and a service life of 2000 hours. - Step 3: Rasper Processing

The material enters the Tire Rasper Machine, where high-speed rotating rasping rollers further refine the coarse shreds into uniform 0.4-0.8 inch pellets. At the same time, it loosens the bond between rubber and steel wire, peeling the steel wire from the rubber to prepare for magnetic separation. - Step 4: Magnetic Separation

A multi-stage magnetic separator (magnetic field strength ≥14,500 Gauss) separates steel wire. The drum-type magnetic separator continuously adsorbs steel wire from rubber pellets, achieving a final 99.9% wire removal rate. The separated steel wire can be further cleaned with a Steel Cleaning Plant or directly baled with a Steel Baler and sold to steel wire recyclers. - Step 5: Final Product Collection

0.4-0.8 inch wire-free rubber pellets and pure steel wire are collected via conveyors. The rubber pellets have a moisture content <5% and ash content <10%, and can directly enter downstream application links.

Ⅲ. Core Component Parameters of Wire-Free Tire Shred Recycling Equipment

The system consists of 3 core devices, with key parameters matching upstream and downstream requirements:

- Tire Shredder: Feed size ≤4 inches, discharge size 1.2-2 inches, processing capacity 1.1-5.5 short tons/hour, motor power 75-150 HP, equipment dimensions (L×W×H) approx. 14.8×7.2×9.2 feet.

- Tire Rasper Machine: Feed size ≤2 inches, discharge size 0.4-0.8 inches, wire removal rate ≥99.9%, processing capacity matching the shredder, motor power 100-215 HP, equipment weight approx. 13-22 tons.

- Magnetic Separator: Feed is 0.4-0.8 inch steel-containing rubber pellets, steel wire purity 97-98%, processing capacity 1.1-5.5 short tons/hour, magnetic field strength 14,500-18,000 Gauss, drum diameter 12-20 inches.

Ⅳ. 7 Core Advantages of Wire-Free Tire Shred Recycling Equipment

The system’s Feature design is fully adapted to the actual needs of tire recycling:

- Efficient Wire Removal: Multi-stage magnetic separation + rasping cooperation achieves a 99.9% wire removal rate, ensuring rubber pellets are pure and free of impurities to meet downstream strict “wire-free” requirements.

- Pure Physical Processing: Operates at room temperature throughout, with no chemical reactions or high-temperature heating, no dioxins, oil fumes, or other secondary pollution, complying with EU REACH and US EPA environmental standards.

- Adjustable Pellet Size: By adjusting the rasping machine’s roller gap, rubber pellets can be adjusted to 0.4 inch, 0.6 inch, 0.8 inch, etc., to adapt to different customer size requirements.

- Multi-Product Output: Simultaneously produces high-quality wire-free rubber pellets and recyclable steel wire. Rubber pellets can be used for mulch or TDF fuel, and steel wire can be monetized independently, increasing project profit points.

- Automated Operation: Equipped with a PLC control system, enabling full-process automation of feeding, crushing, magnetic separation, and collection. It is easy to operate, requires only 1-2 operators, and has high production stability.

- Eco-Friendly and Energy-Saving: Operates at room temperature without heating, with an energy consumption of only 33-55 kWh per ton of pellets. No wastewater or exhaust emissions, no secondary pollution, aligning with the “zero-carbon recycling” industry trend.

- Wide Application Range: Can process all types of waste tires, including passenger car tires, truck tires, OTR tires, and agricultural tires. No equipment replacement is needed to adapt to different raw materials.

Ⅴ. 7 Application Scenarios of Wire-Free Tire Shreds

Purified wire-free rubber pellets (Tire Wire Free Mulch) cover multiple end-use scenarios:

- Landscaping and Gardening Mulch: Used for ground cover in gardens, green belts, and parks. It suppresses weed growth, retains soil moisture, and improves landscape aesthetics.

- Playground Surfaces: Serves as a cushioning layer material for children’s playgrounds and parent-child parks. It enhances surface elasticity and reduces the risk of bumps and falls, complying with EU EN 1177 safety standards.

- Asphalt Supplement: Added to asphalt to improve road crack resistance and skid resistance, extending road service life by 2-3 years. Suitable for the maintenance of municipal roads and highways.

- Safety Mat Surfaces: Used for safety cushioning mats under sports venues, fitness facilities, and climbing walls. It enhances sports protection performance and reduces sports injuries.

- Sports Field Surfaces: Serves as the base material for plastic running track (plastic running track → synthetic tracks), tennis courts, and basketball courts. It enhances surface elasticity and wear resistance, improving sports experience.

- Non-Slip Mats: Used for non-slip mats in wet scenarios such as swimming pools, bathrooms, and kitchens. It improves walking safety and prevents slip accidents.

- TDF Fuel Raw Material: After further crushing into 2-6 inch pellets, it can be used as Tire-Derived Fuel (TDF) in cement kilns, industrial boilers, and other scenarios to replace coal and reduce carbon emissions.

Wire-free tire shred recycling equipment is the “purification hub” in the tire recycling industry chain—through 5-step physical processing, it achieves a 99.9% wire removal rate and simultaneously produces high-value rubber pellets and recycled steel wire. It solves the pollution problem of waste tires and provides low-cost, eco-friendly raw materials for downstream industries such as landscaping, building materials, and energy. With the advancement of circular economy policies, such equipment will become the core support for tire recycling projects to achieve “high profit and zero pollution”, helping investors obtain stable returns in the environmental protection track.

Would you like me to help you optimize the keyword density and placement of this English article to improve its ranking in Google searches?