Wondering how waste tires are transformed into raw materials for plastic running track (plastic running tracks)? This article will give you detailed answers about the production processes, environmental compliance standards, and application scenarios of tire rubber granule factories, helping you understand the “black magic” in the circular economy.

I. What is a Tire Rubber Granule Factory? Understand Its Core Value in 3 Minutes

Every year, 1.5 billion waste tires are generated globally. If all of them were landfilled, they would occupy more than 2,000 acres of land. Tire rubber granule factories are the key to solving this “black waste” problem: through automated production lines, waste tires are turned into uniformly sized rubber granules and reused in fields such as sports and construction.

According to data from the European Tyre Recycling Association, 58% of the 280 million waste tires generated annually in the EU have been recycled through rubber granule factories, reducing pollution by more than 70% compared to traditional landfilling.

II. Production Process of Tire Rubber Granule Factories: 6 Steps to Transform Waste Tires

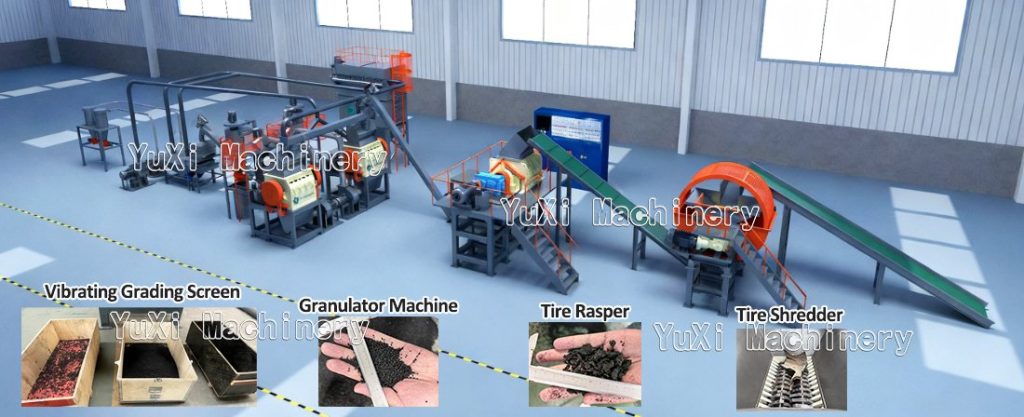

Many people are curious about how a rubber granule is made. The production line of a tire rubber granule factory goes through these core steps:

- Pretreatment: “Subtraction” for Tires

Waste tires first enter a shearing machine to cut off the bead (the metal ring at the edge of the tire), then are cut into rubber blocks. Magnetic separation equipment is used to separate residual metal wires—this step ensures the purity of the granules. If metal residue exceeds 0.3%, the elasticity of the product will be reduced. - Crushing and Grinding: From “Blocks” to “Granules”

Rubber blocks first pass through a coarse crusher to become 5-10mm coarse granules, then enter a fine crusher to adjust the screen size and produce 1-4mm fine granules (the most common specification). For more refined products, a grinder is used to produce rubber powder. - Screening and Classification: “Sizing” the Granules

Granules are classified through a vibrating screen:

Fine granules below 1mm: Used as filler for rubber products;

Medium granules of 2-3mm: Core raw material for plastic running tracks and fitness equipment;

Coarse granules above 4mm: Used for roadbed filling and sound insulation materials. - Cleaning and Drying: Making Granules “Clean”

Granules enter a cleaning tank to remove dirt with high-pressure water and environmentally friendly detergents, then are dried at a low temperature of 55°C in a dryer to ensure the moisture content is below 2.5%—this prevents the granules from mildewing and producing odors.

III. Applications of Products from Tire Rubber Granule Factories: 3 Major Fields Beyond Plastic Running Tracks

The application scenarios of products from tire rubber granule factories are far more extensive than imagined:

Sports and Fitness Field: Double Guarantee of Safety and Elasticity

- Plastic running tracks: Rubber granules mixed with polyurethane glue form an elastic surface layer, reducing sports injuries for athletes by more than 35%;

- Gym floors: Shock-absorbing floors can absorb 65% of the impact force during exercise, protecting joints;

- Playground safety mats: Colorful granule mats can buffer children when they fall, reducing the risk of injury by 85%.

Construction and Municipal Field: A New Choice for Green Building Materials

- Roadbed filling: Rubber granules mixed with asphalt for pavement can improve crack resistance by 40% and reduce vehicle noise by 18 decibels;

- Sound insulation materials: The porous structure can absorb 75% of sound waves, used for sound insulation layers in elevator shafts and machine rooms;

- Roof waterproofing: Mixed with waterproof materials, it can extend the service life of waterproofing by 3-4 years.

Industrial and Agricultural Field: Extended Chain of Circular Economy

- Filler for rubber products: Adding granules when producing new tires can reduce raw material costs by 20% and improve wear resistance by 25%;

- Agricultural insulation layer: Laying under greenhouse floors can increase soil temperature by 3-4°C and reduce heat loss.

IV. Environmental Controversies of Tire Rubber Granule Factories: Real Answers to 3 Questions

- How to Handle Dust and Noise?

Formal tire rubber granule factories are equipped with bag-type dust removal equipment, with dust emission concentration below 5mg/m³; sound insulation covers are used to control noise within 75 decibels, complying with EU industrial boundary standards. - Will Microplastics Pollute the Environment?

Currently, the industry has developed “degradable rubber granules”. After adding bio-based materials, the granules can decompose naturally within 4-6 years; the microplastics generated by the wear of ordinary granules are far lower than the emission level of plastic packaging. - Is the Recycling System Perfect?

The EU has established a waste tire recycling network in 27 countries. The proportion of recycling by formal tire rubber granule factories has increased from 42% in 2018 to 71% in 2024, and the proportion of small workshop processing has dropped to 12%.

V. Future of Tire Rubber Granule Factories: 2 New Tracks Worth Paying Attention To

- New Energy Field

Rubber granules can be used to produce diaphragm materials for lithium batteries, improving battery safety by 30%. Currently, 5 leading battery factories have started cooperative testing. - 3D Printing Materials

Elastic materials made by mixing rubber granules with PLA can be used for customized protective gear, insoles and other products, which are 35% lighter than traditional materials.

VI. Common Questions About Tire Rubber Granule Factories: Answers to 5 User Concerns

- What is the Price of Granules from Tire Rubber Granule Factories?

The price of 1-4mm granules is 220-320 Euros per ton, varying by manufacturer due to process and purity. - How to Judge the Quality of Granules?

Check 3 indicators: metal residue < 0.3%, moisture content < 2.5%, tensile strength > 3.5MPa. - How Long Can Granules Be Used?

The service life of granules in plastic running tracks is about 10-12 years, and that of granules for building filling can reach more than 18 years. - Can Individuals Recycle Tires and Sell Them to Factories?

Yes. Most tire rubber granule factories recycle waste tires at 1.5-2.2 Euros per kilogram (depending on the size of the tire). - Will Granules Have an Odor?

Granules produced by formal factories undergo low-temperature drying and deodorization treatment, and the odor will dissipate within 48 hours, complying with environmental standards.