Are you looking for information on “how to dispose of waste tires” or “clean energy alternatives to coal”? Tire TDF (Tire-Derived Fuel) is the solution that turns “black waste” into “green energy”—it not only diverts 1.5 billion waste tires generated globally each year but also reduces carbon emissions by 15% for cement kilns and paper mills, with a calorific value 10% higher than coal. Today, we break down its production process, application scenarios, cost-benefit analysis, and industry trends in detail.

Ⅰ. What is Tire TDF? Why Is It a New Environmental Choice?

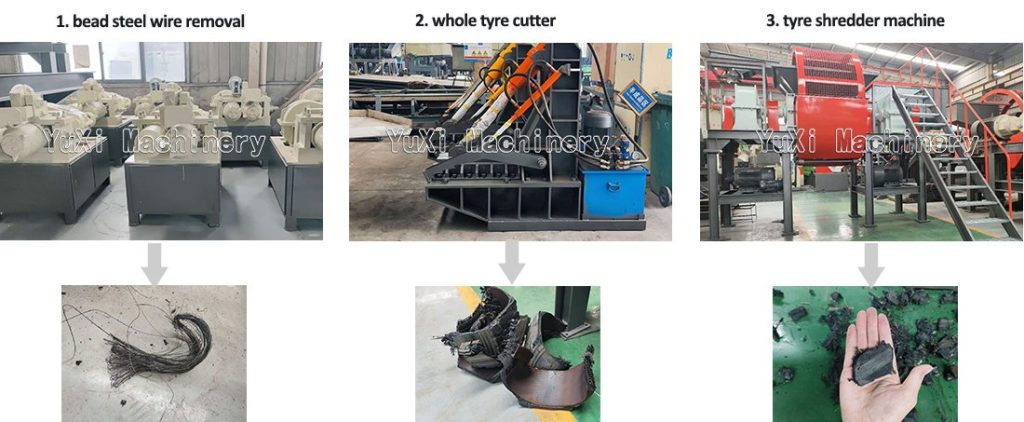

Tire TDF (Tire-Derived Fuel) refers to 2-6 inch uniform rubber pellets obtained by physically processing waste tires through 3 steps: “steel bead removal → cutting → shredding”. Its core parameters are as follows:

- Calorific value: 18,000-20,600 BTU/lb (coal is about 17,000-19,000 BTU/lb)

- Moisture content: < 5%

- Ash content: < 10%

- Sulfur content: < 1.5%

It has become a new environmental choice due to 3 core values:

- Solving industry pain points: The U.S. generates about 300 million waste tires annually. Traditional landfilling requires 800 acres of land, and incineration releases 0.1-0.3 ng TEQ/m³ of dioxins (EPA standard is 0.1 ng TEQ/m³), while TDF achieves 100% resource utilization.

- Win-win for carbon reduction and cost savings: Data from a U.S. cement company shows that using TDF reduces fuel costs by 22% and annual carbon emissions by 1,090 tons of CO₂e (equivalent to removing 237 cars from the road annually).

- Policy support: The EU’s “Circular Economy Action Plan” requires 100% recycling of waste tires by 2030, and the U.S. EPA classifies TDF as an “acceptable alternative fuel”.

Ⅱ. Turning Tires into TDF: 3-Step Physical Processing (with Equipment Parameters)

Taking YUXI TDF tire recycling plant as an example, the entire system is fully controlled by PLC, processing 2.2-22 short tons of mixed tires per hour without chemical additives or high temperatures. The specific process is as follows:

Step 1: Bead Steel Wire Removal

- Equipment: Tire Debeader

- Principle: Guide the tire into the guide slot, squeeze through 8-inch diameter double rollers (30 RPM) to peel off the rubber from the steel wire. The separated steel wire has a purity of > 99% and can be directly sold to steel mills.

- Capacity: 100-150 passenger car tires per hour per unit.

Step 2: Whole Tyre Cutter

- Equipment: Hydraulic Whole Tyre Cutter

- Parameters: Blade material is AISI D2 (hardness 58-62 HRC), shearing force is 132 short tons, capable of cutting tires with diameter ≤ 55 inches and thickness ≤ 8 inches.

- Advantage: Low blade wear rate—only needs sharpening once every 1,000 tires cut.

Step 3: Tire Shredder Machine

- Equipment: Dual-Shaft Shredder

- Parameters: Shaft material is AISI 4140 (surface nitrided, hardness 55-58 HRC); blades are AISI H13 high-alloy steel (2,000-hour service life, replaceable); shredding chamber size is 47×31 inches.

- Finished product: 2-6 inch uniform rubber pellets with steel wire residue rate < 0.5%.

Ⅲ. 7 Application Scenarios of Tire TDF (with Enterprise Cases)

Tire TDF covers multiple high-energy-consuming industries, with cement kilns accounting for 60% of applications, paper mills 15%, industrial boilers 10%, civil engineering 8%, waste incineration plants 5%, biomass power plants 1%, and recycled rubber production 1%.

Scenario 1: Cement Kiln Fuel

- Case: A U.S. cement production line co-fires 20% TDF, consuming 3,300 short tons of waste tires annually, saving $1.32 million in coal costs and reducing carbon emissions by 1,980 tons of CO₂e.

- Advantage: The 2,550°F high temperature of cement kilns completely decomposes chlorine in rubber, avoiding dioxin formation, and ash can be used as “iron correction material” for cement production.

Scenario 2: Paper Mill Fuel

- Case: A Canadian paper mill uses TDF to replace 30% coal, reducing sulfur oxide emissions by 264 short tons annually and cutting fuel costs by 18%.

- Advantage: TDF burns stably and does not cause “coking” issues like biomass fuel.

Scenario 3: Civil Engineering Filling

- Case: A U.S. highway subgrade uses TDF pellets for filling, which is 30% lighter than traditional stone, improves sound insulation by 25%, and reduces construction costs by 10%.

Ⅳ. 5 Core Advantages of Tire TDF Systems (vs. Pyrolysis Technology)

Many people ask, “Which is better: TDF or tire pyrolysis?” Here’s a detailed comparison:

In terms of environmental friendliness, tire TDF physical processing involves no chemicals or high temperatures and produces no secondary pollution, while tire pyrolysis technology generates oil fumes and tar that require exhaust gas treatment. For investment cost, a TDF production line costs $1.1-3.3 million, significantly lower than the $5.5-11 million required for a tire pyrolysis line. In terms of capacity, TDF systems process 2.2-22 short tons per hour, outperforming pyrolysis technology’s 0.55-2.2 short tons per hour. For product flexibility, TDF allows adjustable pellet sizes to meet diverse needs, while pyrolysis only produces oil, gas, and carbon black. Regarding policy compliance, TDF meets EPA/CE standards and is widely accepted, while pyrolysis is restricted in some regions.

In addition, TDF systems have 3 unique advantages:

- High automation: PLC control panel monitors capacity and blade wear in real time, supporting remote debugging.

- Low maintenance cost: Blades can be replaced individually; annual maintenance cost is only 5% of the total equipment price.

- Strong raw material adaptability: Can process 80% new tires + 20% old tires without sorting.

Ⅴ. Industry Trends of Tire TDF: 3x Growth by 2025-2030

According to the Global Tire Derived Fuel Market Report:

- The global TDF market size was $1.32 billion in 2023 and will reach $4.95 billion by 2030, with a CAGR of 19%.

- North America is the fastest-growing market; the U.S. and Canada’s demand share will rise from 28% in 2023 to 42% in 2030.

For enterprises, the payback period of TDF projects is about 2-3 years:

- Raw material cost: $44-66 per short ton of waste tires.

- Finished product price: $176-264 per short ton of TDF pellets.

- Annual profit: A 11 short ton/hour production line yields an annual profit of $2.2-5.5 million.

Ⅵ. Frequently Asked Questions

Q1: Does tire TDF combustion produce dioxins?

A: In high-temperature scenarios (>2190°F) such as cement kilns, dioxins are completely decomposed. For low-temperature boilers, supporting flue gas treatment equipment is required, and emissions can meet EPA standards.

Q2: Can individuals invest in TDF projects?

A: Currently, TDF projects are mainly for enterprises, requiring EPA solid waste disposal permits. A single production line costs about $1.1-3.3 million.