Home » Tire Recycling Machine » Tire Wire Free Mulch Plant

Tire Wire Free Mulch Plant

Tire Wire Free Mulch Recycling Plant is the ultimate machine for mid-stream and steel separation for 20mm wire free chips.

Home » Tire Recycling Machine » Tire Wire Free Mulch Plant

Tire Wire Free Mulch Recycling Plant is the ultimate machine for mid-stream and steel separation for 20mm wire free chips.

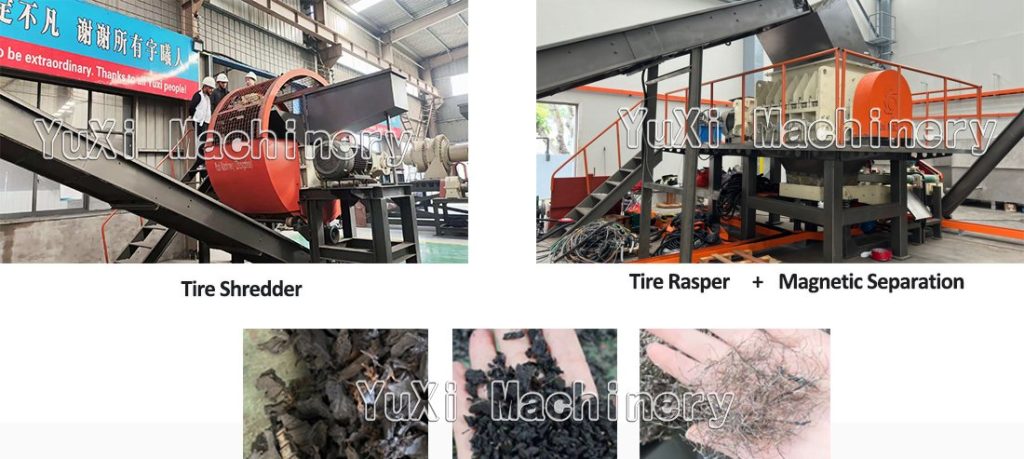

YUXI Tire Wire Free Mulch Plant is the second step in the tire recycling system. At this stage, TDS chips from the r are processed into 10–20mm wire-free rubber chips using a magnetic separator. During processing, scrap tires shredded by our YX Tire Shredder and Rasper are converted into approximately 99.9% wire-free chips.

This plant produces high-quality rubber mulch and separated steel. It is a purely physical processing system, operates at normal temperature, and causes no secondary pollution. The system can further process steel via a steel cleaning plant or compress it using a steel baler for direct sale to smelters.

Raw Material Input: Waste tires are fed into the system via conveyor

Tire Shredder: Primary shredding of whole tires into large rubber pieces

Rasper Processing: Further size reduction and uniform chip formation

Magnetic Separation: Steel wires are removed, separating rubber from steel

Final Product Collection: Smaller tire chips and steel wires are obtained

Landscaping and gardening purposes

Playground surfaces

Asphalt supplement

Safety surfaces

Sports courts surfaces

Safety tiles

Tire shredders is designed to help you turn bulky, used tires into manageable materials for recycling or disposal, saving you both time and disposal costs. Whether you need a high-capacity, heavy-duty shredder or a compact unit for smaller operations, we have solutions to fit your workflow and budget.

Input: Rough tire shreds, less than 100mm

Output:Wire free rubber mulch 10-20mm, 99% liberated steel

Input:10-20mm rubber chips mixed with steel wire and fiber

Output: 97-98% steel wire, rubber with fiber to next stage