Home » Tire Recycling Machine » Tire Rubber Crumb Plant

Tire Rubber Crumb Plant

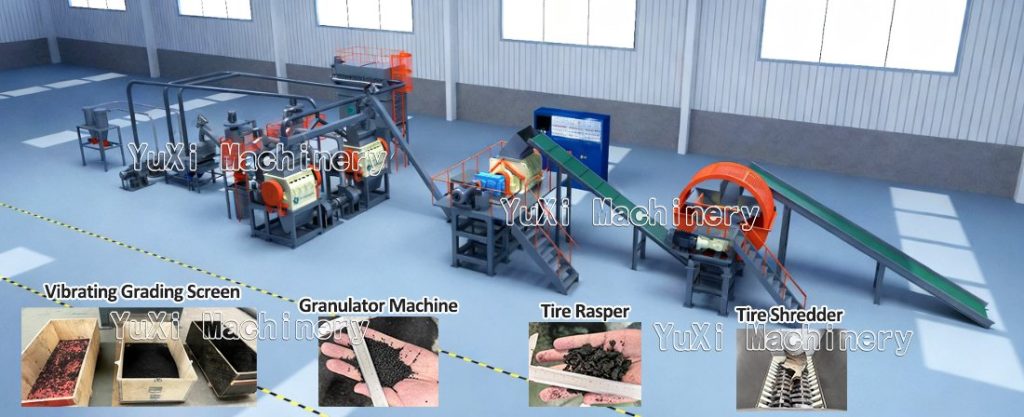

Tire Rubber Crumb Recycling Plant is designed to grind rubber mulch into 1-8mm rubber granules.

Home » Tire Recycling Machine » Tire Rubber Crumb Plant

Tire Rubber Crumb Recycling Plant is designed to grind rubber mulch into 1-8mm rubber granules.

The Tire Rubber Crumb Plant is a key stage in the waste tire recycling process. It processes wire-free tire chips from the Rubber Mulch Plant into high-purity rubber granules, ensuring fiber removal and uniform particle size.

Outputs: High-purity rubber granules (0-5mm), steel, fiber

Raw Materials: Wire-free tire chips produced by the Tire Wire Free Mulch Plant

Granule Characteristics: Fiber removed, uniform size, approximately 99.9% clean rubber crumb

Environmental Benefits: Recovered steel can be melted and reused; textile fibers can serve as high-calorific fuel.

Construction: Rubberized Asphalt for Roads and

Driveways: Bumpers, Floor Tile, Foundation Waterproofing

Geotechnical/Asphalt Applications: Drainage Pipes, Soil Conditioner, Porous Irrigation Pipes, Road Building and Repair

Rubber and Plastic Products: Pipe Insulation and Lining, Garbage Cans, Shoe Soles and Heels, Wire and Cable Insulation

Tire shredders is designed to help you turn bulky, used tires into manageable materials for recycling or disposal, saving you both time and disposal costs. Whether you need a high-capacity, heavy-duty shredder or a compact unit for smaller operations, we have solutions to fit your workflow and budget.

Input: Rough tire shreds, less than 100mm

Output:Wire free rubber mulch 10-20mm, 99% liberated steel

Input:10-20mm rubber chips mixed with steel wire and fiber

Output: 97-98% steel wire, rubber with fiber to next stage

Input: Wire-free chips 10-20mm

Output: Wire free rubber pellet 1-8mm, fiber separated

Input: Rubber granulate & Fiber

Output: Textile free rubber granulate, 99.9% textile

The textile fraction is a residual fraction including nylon,polyester,rayon,aramid and little rubber.