Home » Tire Recycling Machine » Tire Rubber Powder Plant

Tire Rubber Powder Plant

Tire Rubber Powder Recycling Plant is designed to grind 1-8mm rubber granules into 30-120mesh rubber powder.

Home » Tire Recycling Machine » Tire Rubber Powder Plant

Tire Rubber Powder Recycling Plant is designed to grind 1-8mm rubber granules into 30-120mesh rubber powder.

The rubber powder plant is proven to transfer waste tires into a clean rubber powder form with virtually all steel and fiber removed. This scrap tire recycling line a physically processing machine, working in the normal temperature, causing no secondary pollution.

Outputs: High-purity rubber powder (20-120mesh)

Raw Materials: rubber granules produced by the Rubber Mulch Plant

The complete tire recycling plant from A to Z include tire debeader,tire shredder,rasper,granulator and miller. The customer can get different output through the whole line,include chips,rubber blocks,steel wire,rubber granules, rubber powder and fiber.

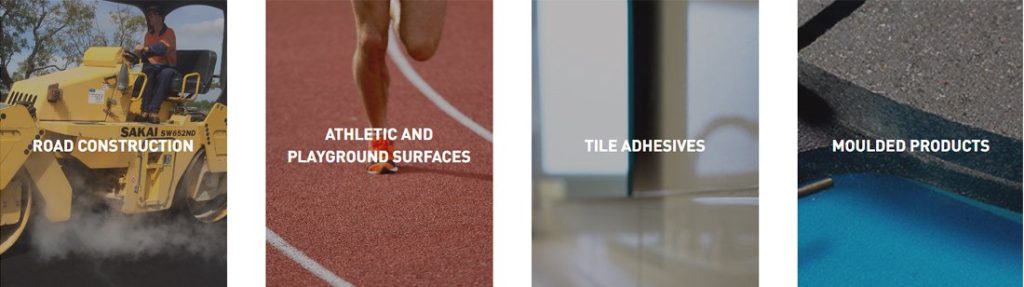

Road Construction: Rubber asphalt, shock-absorbing materials

Sports Facilities: Running tracks, artificial turf infill

Industrial Products: Seals, shoe soles, rubber mats, shock absorbers

Environmental Materials: Recycled rubber boards, fillers

Energy: Rubber-derived fuel.

Tire shredders is designed to help you turn bulky, used tires into manageable materials for recycling or disposal, saving you both time and disposal costs. Whether you need a high-capacity, heavy-duty shredder or a compact unit for smaller operations, we have solutions to fit your workflow and budget.

Input: Rough tire shreds, less than 100mm

Output:Wire free rubber mulch 10-20mm, 99% liberated steel

Input:10-20mm rubber chips mixed with steel wire and fiber

Output: 97-98% steel wire, rubber with fiber to next stage

Input: Wire-free chips 10-20mm

Output: Wire free rubber pellet 1-8mm, fiber separated

Input: Rubber granulate & Fiber

Output: Textile free rubber granulate, 99.9% textile

The textile fraction is a residual fraction including nylon,polyester,rayon,aramid and little rubber.

Input: Rubber granulate smaller 1-8 mm

Output: Rubber powder 20-120mesh, 99.7% purity fine powder