Home » Tire Recycling Machine » Tire TDF Plant

Tire TDF Plant

Tire TDF Plant is designed to turn whole tires into rough shreds chips around 50-100MM.

Home » Tire Recycling Machine » Tire TDF Plant

Tire TDF Plant is designed to turn whole tires into rough shreds chips around 50-100MM.

YUXI TDF (Tire-derived fuel)Plant is designed for recycling all kinds of waste tires, including whole car tires, truck tires, OTR tires, and mining tires.

Non-chemical, no heat generation: This system operates without chemical reactions and without temperature rise, ensuring safe and eco-friendly processing.

Flexible output: It can shred scrap tires into high-quality rough shreds or rubber chips of 50–150mm for collection, TDF production, or further processing.

Clean results: During shredding, tires are cut and recirculated, producing uniform rubber chips with minimal exposed wire.

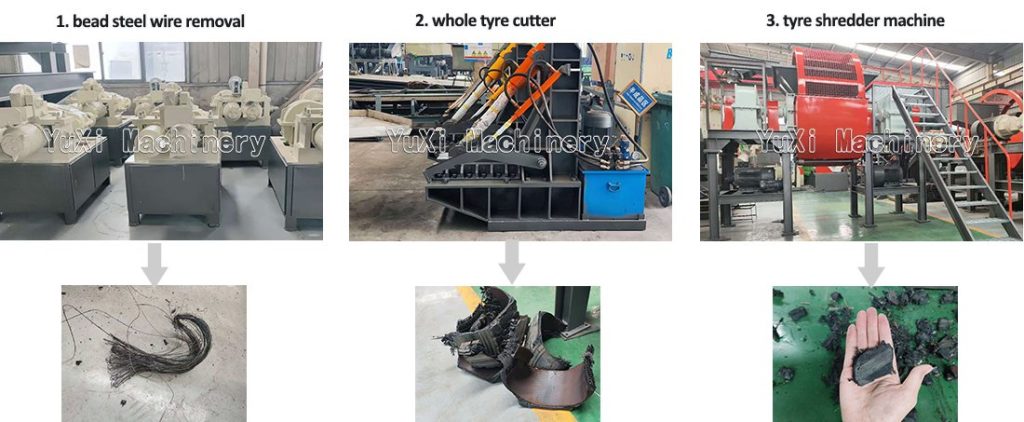

Stage1: Bead steel wire removal

Stage2: Whole tyre cutter

Stage3: Tyre shredder machine

The tire debeader is used to remove the bead wire from the ring of tires. Treat the side wall and the inner mouth of the tire, and all internal steel cables are removed. The inner mouth of the tire is directed to the guide groove,and the limiting device causes the inner mouth of the tire to enter the middle of the two rollers, and the outer covering rubber of the steel wire is separated from the steel wire by the Two rollers facing each other. Thus obtaining a complete tire.

Cutting machine Knife material: Cr12

The basic principle is: the motor drives the hydraulic system and the oil cylinder, and the tire is placed between the two blades to promote the shearing force of the two blades to achieve the shearing effect.

Features: The equipment has large shearing blades, good shearing effect and low.

tire shredder is a machine that physically breaks down used tires into smaller, more manageable pieces for recycling.

Double Shafts: 40Cr material, the hardness after surface nitriding treatment is 55-58 HRC

ZWZ Bearings: Top 3 Manufacturers in China.

One-piece blade,H13 high alloy steel material, hardness 55-58 HRC,long working life.